How to choose UPS battery

When it comes to choosing battery for an uninterruptible battery, you need creative approach. Of course, you can always buy battery with similar characteristics to the one that has already been installed (operating voltage, capacity and dimensions). Such step is justified when the old battery was completely satisfied, but it has worn out and needs to be replaced. Much more often, there is need to increase the energy intensity of the assembly in order to extend the battery life of the equipment backed up from the “uninterruptible” device. Less often, there are situations associated with the need to select battery with smaller capacity so that it has time to charge according to blackout schedules.

Larger battery for the UPS significantly extends the runtime of the connected load. But here it is important to take into account the magnitude of the charging current (this is discussed below in the corresponding section). In short, low-power “uninterruptible power supply” with an energy-hungry battery simply will not be able to deliver the proper charging current and the battery will take too long to charge. Charging with low currents is the most gentle for the battery and prolongs its service life, however, with regular power outages, the user will face the problem of constant undercharging of the battery. Plus, the dimensions of the increased capacity battery will certainly be larger than that of the “native” battery - the battery will not fit in the “uninterruptible” case.

As for choosing smaller battery than originally envisaged, it is not recommended to cut the power consumption excessively - half smaller battery can overheat due to abnormal loads. It is advisable to select the battery capacity by about 20 - 30% less than the original one, nothing more.

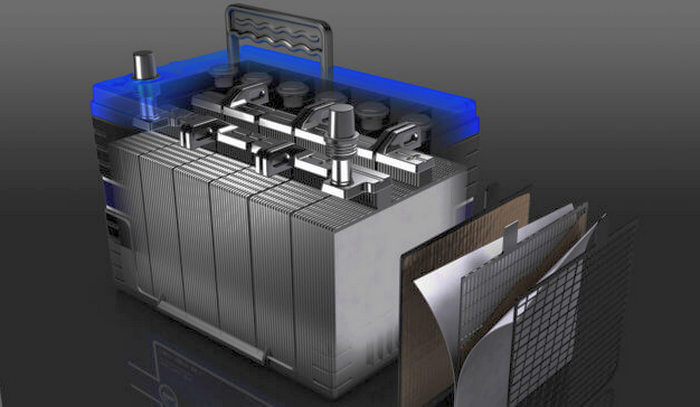

The principle of operation of all batteries for “uninterruptibles” is the same - they accumulate an electric charge and give it away in the event of interruptions in the power supply from the network. The differences lie in the design features of the structure of the batteries. There are several common battery technologies on the market today. Let's look at their features to make it easier to choose the required solution technically and in terms of the thickness of the wallet.

Technology

Gel (GEL)

Subspecies of classic lead-acid batteries, which are familiar to many in the automotive battery segment. GEL batteries use gel-like electrolyte. Among lead counterparts , GEL batteries are best adapted to the cyclic nature of work, and they can also easily withstand deep discharge. Gel batteries can remain uncharged for long time without losing their original properties.

|

| GEL batteries are filled with electrolyte in gel state. |

In "uninterrupted" batteries of the GEL type are used infrequently. This is due to the fact that they are tailored for the operation scheme, when the battery needs to supply the load for long time with discharge to almost zero, then charge and again provide long-term autonomous power. For buffer mode, which is typical for most UPSs, this technology is not particularly suitable for number of reasons. It makes sense to purchase gel batteries in cases where the “uninterruptible power supply” has to be turned on almost daily and for long time (for example, in unstable networks with constant and long power outages). GEL batteries are best combined with advanced Online type UPSs, where the battery is directly involved in voltage stabilization, and therefore it is constantly involved.

The main disadvantages of the technology include increased sensitivity to short circuits and rather expensive cost for the mass consumer segment.

Glass cloth (AGM)

Another type of maintenance-free lead-acid battery. Inside the case of AGM batteries is the electrolyte in an absorbed state (Absorbed Glass Mat). The compartments of such battery are filled with porous fiberglass material, which contains acid. This technology allows you to eliminate the release of gases and make the battery sealed.

AGM batteries fit well into the concept of buffer operation of uninterruptible power supplies, when the “uninterruptible power supply” stands ready for long time in order to briefly support the power supply in the event of failure. Their distinguishing features include long service life (over 10 years), no “memory effect”, low self-discharge, suitability for installing the battery in any convenient position.

|

| In AGM batteries, the electrolyte is absorbed by finely porous glass fibers. |

The disadvantages of AGM technology are predetermined by poor overcharge tolerance. However, when using high-quality power controller or built-in BMS-board, this problem is completely reduced to nothing.

Carbon

An advanced type of lead-acid battery with lead plates that are enriched with carbon (carbon). This reduces the likelihood of thermal runaway - when short circuit can occur due to heating of the electrolyte. Carbon batteries have service life of up to 15 years, but they have very specific requirements for the charging mode. They are recommended to be discharged at least 30% and charged no more than 90%. Carbon batteries are only suitable for UPS with the ability to set the appropriate charging parameters.

Lithium-ion (Li-Ion)

Li-Ion batteries use a solid substance containing lithium metal as an electrolyte. Such properties make the battery more compact and endow it with resistance to constant discharge. Lithium-ion UPS batteries are not subject to the "memory effect" and are able to charge fairly quickly. The service life of lithium-ion batteries is also decent - individual copies of such batteries can withstand over 1500 charge / discharge cycles.

This option also had some drawbacks - first of all, Li-Ion batteries show increased sensitivity to low or high temperatures. And when overloaded, Li-Ion battery can catch fire or even explode. Together with such batteries, it is important to use high-quality power controller.

Lithium iron phosphate (LiFePO4)

The development of lithium-iron-phosphate batteries was carried out in order to eliminate some of the shortcomings of the original Li-Ion technology. Batteries of the LiFePO4 type boast large number of charge/discharge cycles, chemical and thermal stability, tolerance to low and high operating temperatures, and short charge time using high currents. LiFePO4 batteries can be charged up to zero temperature on the Celsius scale.

|

| Something like this looks like one of the factory assembly steps for LiFePO4 batteries. |

LiFePO4 batteries are not afraid of overloading and overcharging, they perfectly cope with high peak loads and keep stable operating voltage until almost completely discharged. Also, such batteries give out high efficiency, have long service life and have low level of self-discharge. LiFePO4 battery packs are suitable for UPS backup of wide variety of electronic equipment.

How to calculate the required battery capacity

To determine the required battery capacity, it is important to calculate the total power of the reserved load, which is added according to the passports of electrical appliances or the power table:

| power tool | Appliances | ||

|---|---|---|---|

| Consumer | Power, W | Consumer | Power, W |

| Electric jigsaw | 250-700 | Electric lamps | 5-50 |

| electric grinder | 300-1100 | TV | 100-400 |

| Drill | 400-800 | Fridge | 150-600 |

| electric planer | 400-1000 | Computer | 400-750 |

| Perforator | 600-1400 | Vacuum cleaner | 1000-2000 |

| Grinder | 650-2200 | Hair dryer | 450-2000 |

| Circular Saw | 750-1600 | Iron | 1000-2000 |

| High pressure pump | 2000-2900 | Toaster | 500-1000 |

| electrical appliances | Coffee maker | 800-1500 | |

| Consumer | Power, W | Oven | 2000-3500 |

| Water pump | 500-900 | Electric kettle | 2000 |

| Electric motors | 550-3000 | Heater | 1000-2000 |

| fan heater | 750-1700 | electric stove | 1100-6000 |

| Compressor | 750-2800 | Boiler | 1500-2000 |

| Air conditioner | 1000-3000 | Microwave | 700-1000 |

| Circular saw | 18000-2100 | Washing machine | 1000-2500 |

Knowing what kind of load is supposed to be backed up from the "uninterruptible", you can start calculating the estimated battery capacity for specific operating time. For this, the following formula is used:

E = (P • T) / (V • K),

- E is the battery capacity in amp-hours (Ah);

- P is the total power of the connected equipment in watts (W);

- T is the load backup time in hours (h);

- V is the battery voltage in volts (V);

- K is the coefficient of the used capacity, which takes into account the part of the spent charge for the power supply of the load; as a rule, an average variant of 0.8 is taken here, less often the coefficient is taken as “unit”.

Suppose we are faced with the task of establishing backup power from the UPS to the heating boiler and its control electronics for up to 4 hours. The power of all connected equipment is about 100 W, the battery voltage is 12 V (one 12-volt battery or two 6 V batteries connected in parallel):

(100 • 4) / (12 • 0.8) = 41.66 (Ah)

For our purposes, battery with capacity of up to 50 Ah will do - this is taking into account almost 20% in reserve. Or you can purchase several batteries of smaller capacity, which in total provide the required energy reserve. In heating circuits with a circulation pump, it is additionally necessary to add 50 to 100 W of power from above (depending on the specific pump model) and make calculations for the specified power parameters.

- parallel connection sums up the voltage of the batteries (three conditional batteries of 6 V each give voltage of 18 V in total);

- the sequential circuit allows you to increase the total capacity of the assembly (two conditional batteries with capacity of 40 Ah give total energy capacity of 80 Ah).

There are also reverse situations when the battery capacity is known, but it is necessary to calculate the backup power supply time for the load. In this case, the formula is slightly modified:

T = (E • V • K) / P,

- T is the load backup time in hours (h);

- E is the battery capacity in ampere-hours (Ah);

- V is the battery voltage in volts (V);

- K is the coefficient of the used capacity, which takes into account the part of the spent charge for the power supply of the load; as rule, here they take an average variant of 0.8, less often the coefficient is taken as “unit”;

- P is the total power of the connected equipment in watts (W).

Suppose, having UPS with 12-volt battery with capacity of 50 Ah, it is necessary to organize backup power for the refrigerator. How long will it last during power outages? For example, let's take that the compressor of refrigeration unit with power consumption of 200 W runs for about 2 minutes with an interval of 10 minutes. Its average power consumption is 200 W • 2 min. / 10 min. = 40 W. We take this figure as the value of P :

(50 • 12 • 0.8) / 40 = 12 (hours)

When connecting other equipment, it is required to add to the energy consumption parameters of the refrigerator and its power, and then re-calculate the estimated operating time of the total load.

Charging current

An important factor when choosing batteries for UPS is the charging current. This is the current strength that is supplied to the battery from the "uninterruptible". If you install regular battery, you don’t have to worry about this parameter, but it’s still important to check it. Otherwise, the charging current must be taken into account. In the characteristics of the battery, it is indicated infrequently, however , you can roughly calculate the indicator by dividing the battery capacity by 10. Those. for conditional battery with capacity of 100 Ah, the charging current should be about 10 Ah (which means it will charge in about 10 hours). Significant excess of the charging current leads to rapid wear of the battery, and charging with low currents does not bode well, but it can take long time.

We make reservation that what has been said is true for ordinary conditions. In the rhythm of life with blackouts on schedules and off schedules, compromises can be made. Charging the battery for 10 hours is often an unaffordable luxury. Accordingly, it is important to prioritize correctly - charging the battery with higher currents is quite acceptable, although it comes at the expense of battery longevity. It is possible to halve the charging time of conditional battery by 100 Ah when using charging current of 20 A, battery with capacity of 50 Ah - with current of 10 A, etc. The battery in such cases will "live" less, but you will not be left without backup power.

|

| When choosing battery for replacement UPS, it is necessary to take into account the amount of charging current for new battery. |

In some models of "uninterruptible devices" with the ability to connect to PC or smartphone (for example, via Bluetooth network) there is calibration mode that allows you to select and set the optimal amount of charging current for particular battery assembly or your own preferences.

Can starter (car) batteries be used with the UPS?

Starter or starter batteries operate in two main modes: short-term discharges with high current when the starter is running and infrequent long-term discharges with low current when consumers are running on the engine off. Uninterruptibles, on the other hand, suggest slightly different scheme of work with frequent deep discharges of the battery, which traditional lead-acid car batteries do not like at all. Together with the UPS, their work is quite possible, but only under certain conditions. The main one is that the operating voltage of the "uninterruptible" must be multiple of 12 V. If it is lower (for example, 4 or 6 V), you will not be able to connect the car battery; higher, but multiple of 12 V - you can assemble an assembly of several car batteries connected in series, but the capacity of such solution may be excessively large.

|

| Starter car batteries are not particularly suitable for use with UPS. |

Another limiting factor in the use of lead-acid car batteries in conjunction with UPS is the fire and explosion hazard of the charging process (when the liquid electrolyte boils, hydrogen and oxygen are released, and the case of classic starter batteries is usually leaky and the removal of such "emissions" is carried out literally "on street"). Also, car batteries have slightly higher operating voltage, which promises constant undercharging of the battery, they are not designed for long-term operation and deep discharges (over 50% of the original capacity). In the bottom line, they are more suitable as temporary solution for emergency situations, but they do not look like reliable battery option for uninterrupted batteries. Still, starting batteries are strikingly different in the nature of their work from traction batteries, which are commonly used in UPSs.

Gel automotive batteries, AGM models and EFB subtype batteries are deprived of many of these flaws. They often calmly withstand constant charge / discharge, are assembled in sealed case, however, they are inferior in terms of durability to specialized batteries for UPS. More details about these and other types of batteries are described in the article "Common types of batteries".

UPS with well-chosen battery will help to establish autonomous operation of computer and the most popular household appliances in case of frequent power outages. As an alternative, they learned how to make assemblies from an auto-inverter and starter battery. More details about these are described in the material "How to choose car inverter for creating autonomous power systems from car battery".

Also relatively recently, portable charging stations have entered the arena, which have proven themselves exclusively in positive way. Many models of mobile power plants provide a UPS function, which provides the ability to automatically switch to power the connected load during power outages. "What are portable charging stations?" - Read the article of the same name.

Articles, reviews, useful tips

All materials